Conveyor Engineering & Manufacturing

Guardian Shaft Seals

Product Description

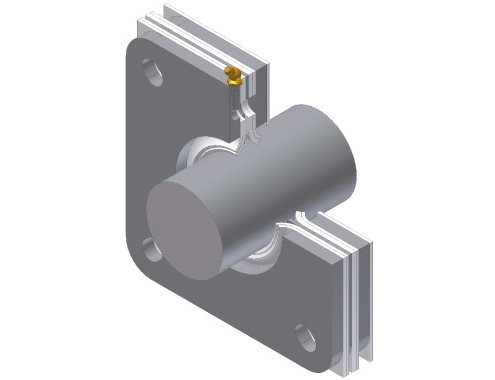

Our revolutionary Guardian™ Grease Purged Seal is a major step forward. Unlike most others, our Guardian™ seals are constructed of elastomers that center on the shaft – and flex with it.

How Guardian™ Seals work:

Our revolutionary seal is comprised of multiple nitrile seals stretched over the rotating shaft. Some seals face inward (toward the product), while some face outward (away from the product).

The key to our Guardian™ seal’s success are the inward seals – they maintain a tighter seal than those to the outside and decrease the likelihood of grease contamination reaching the product. The gap between these two seals is filled with grease through a remote “zerk” or other fitting.

Do you have questions?

Contact our engineering team here.

Guardian Shaft Seals

Additional Features

- Effective up to 215º F and 5 psi (higher for short durations): We are continuing to test elastomers and grease that will tolerate even higher temperatures and pressures.

- HT Version Effective up to 400º F: Nitrile elastomers are replaced with Viton for more extreme applications.

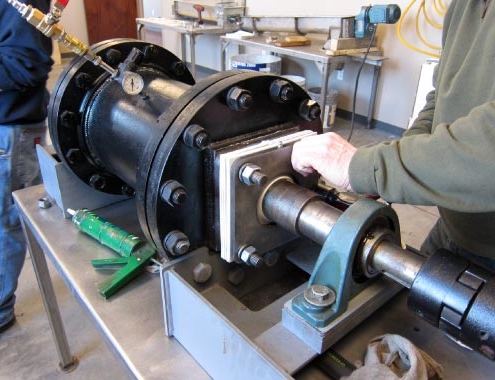

- Split Version Available: Our fully split version will replace existing seals without costly removal of bearings and drive components.

- Made with Heavy Gauge Elastomers: Nitrile, Viton or other compounds provide you with years of useful life in most applications. This design helps to create a seal that is more flexible and tighter, allowing it to conform to the shaft and remain effective even in high “run-out” situations.

- Food Grade: When combined with the proper grease, the Guardian™ seal is FDA/USDA approved and an excellent fit for food grade applications. We have had very good results using SKF LGFP 2 grease in these situations.

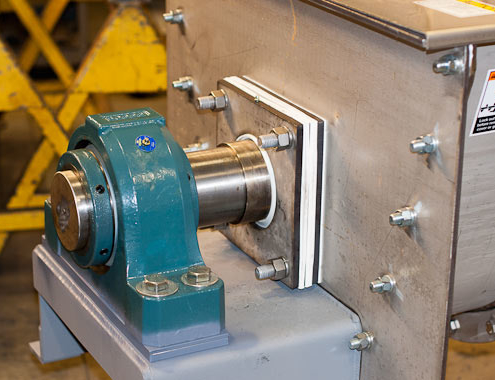

- Easy Retrofit & Low Profile: The Guardian™ seal will replace most waste pack and air purge seals already on the market with ZERO interchangeability problems. Throw out that leaky waste pack. Toss the air purge seals (and the regulator and air lines as well). Simply bolt the Guardian™ seal in behind the flange bearings you’re currently using and you’re ready to go. What about a leaking flanged/packing gland seal? We can create a custom seal that will fit – and at a reasonable cost.

- Custom Designs Available: Guardian™ seals can be modified to fit your company’s needs and increase the pressure resistance of your seal. The grease used can be petroleum based, synthetic, or food grade. Gaskets can be installed to ensure any grease purge leakage occurs away from the product. Custom metal components, special patterns and stack-up dimensions and higher pressure resistance are a simple matter.

- Successful in Difficult Applications: We have had repeated success sealing against hexane, high head loads of sugar, cooled fly ash, etc. The seals have lasted more than a year with only lubrication required.

Guardian™ seals are as close to installing and forgetting a seal as you can get.

Product Inquiry

Need information on a product or service or simply have a question? Email our team here.

Support/Sales

Do you know what you need and are looking for next steps? Contact our team here.

Custom Items Shipped

Happy Customers

Wonderful Years in Business