Conveyor Engineering & Manufacturing

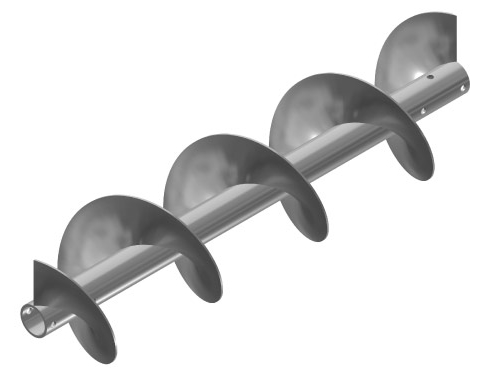

Large Screw

Product Description

Conveyor Engineering & Manufacturing can fabricate single screws up to 60″ in diameter and 50′ in length. Building a large screw isn’t as simple as scaling up from a standard screw. Many things need to be covered in the design phase:

- Deflection: Added weight and span length must be taken into consideration to stay inside of design parameters.

- Material Properties: Fatigue stress becomes much more important as size increases. Stainless steel, for example, can’t handle fatigue as well as carbon steel so the deflection limit must be lower when building large, stainless steel screws.

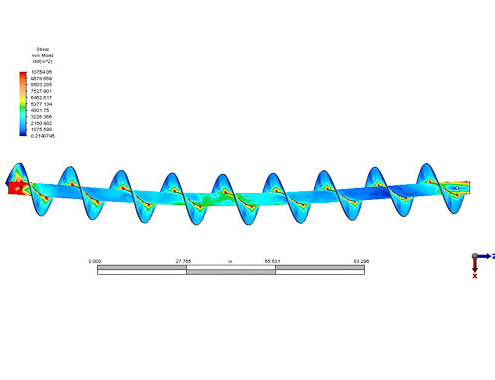

- FEA Stress Analysis: Variations in shafts, flighting, paddles, etc. that typically coincide with large screws can result in complex stress calculations that can only be handled properly with FEA software and the experienced use of it. We offer FEA as a standard service for screws in this category.

- Pipe Length Restrictions/Weld Analysis: Many large screws exceed available pipe lengths. In this case, the pipe must be spliced together. This requires high quality welds that will withstand stress relieving that occurs as the screw cycles through compression and tension phases as it rotates. Shot peening, needle peening, thermal treatment, etc. are all processes we can apply to stress relieve splice welds before shipping. Results can be confirmed with X-ray examination.

Product Inquiry

Need information on a product or service or simply have a question? Email our team here.

Support/Sales

Do you know what you need and are looking for next steps? Contact our team here.

1,200,000+

Custom Items Shipped

Over 1,200+

Happy Customers

and 42

Wonderful Years in Business