Conveyor Engineering & Manufacturing

Screw Feeders & Live Bottoms

Product Description

Screw Feeders are used to control the flow rate of free flowing, bulk material from a bin or hopper. The inlet section of the trough is designed to be flooded (100% full).

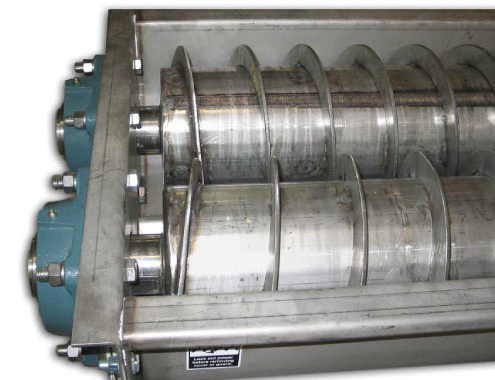

A shroud (curved cover) or tubular trough helps restrict the flooded area to only the inlet section. The screw under the inlet, and sometimes the trough as well, are modified to convey a metered amount of material per revolution of the screw. Modifications may include changes in the flighting diameter, pitch, pipe diameter, trough shape, etc.

Screws with uniform diameter and pitch will convey material from the rear of the inlet opening first. This can create flow issues with some materials because only a portion of the inlet is actually used so the bin or hopper doesn’t discharge evenly.

Pockets of material don’t move and may clump, degrade over time, etc. The answer to this problem is to use the screw and trough modifications to create “Mass Flow” which means to draw material evenly across the full length of the inlet. This requires a screw with variable pitch flighting, cone shaped pipe and/or tapered diameter.

Screw Feeder/Live Bottom

RFQ Spec Sheet

Screw Feeders & Live Bottoms

Product Variations

Single Screw Feeder

Single screw feeders help to meter flow rate of material. We offer many modifications of screw feeders to best fit your needs.

Twin Screw Feeder

All of the single screw variations are also available as twins. This increases capacity and allows for wider inlets and discharges which often improves performance for less free flowing materials.

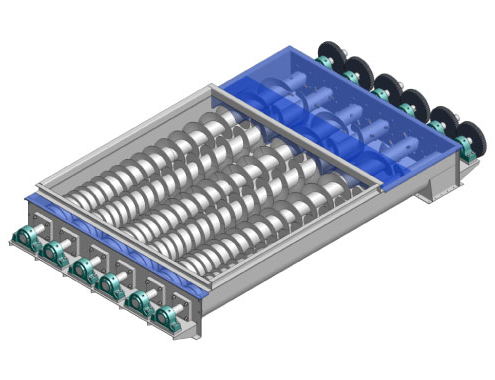

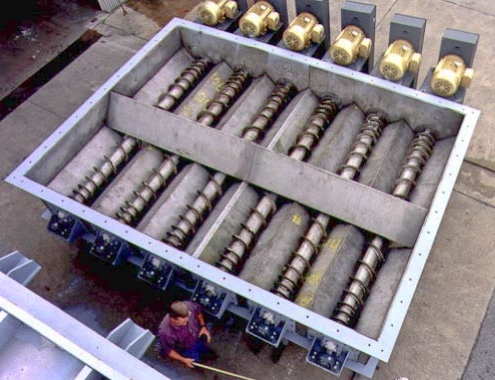

Multiple Screw Feeder (Live Bottom)

Designed for use on straight sided bins, Live Bottoms are composed of a number of feeder screws working in tandem to serve as the bottom of the bin. Material is drawn out equally from the full length and width of the bin. The Live Bottom Feeder is used to its best advantage with materials that tend to pack or bridge.

Many variables need to be addressed when designing an efficient Screw Feeder / Live Bottom including product particle size & shape, moisture content, head loads, etc. so past experience is often crucial.

Screw Conveyor

Component and Design Manual

Product Inquiry

Need information on a product or service or simply have a question? Email our team here.

Support/Sales

Do you know what you need and are looking for next steps? Contact our team here.

Custom Items Shipped

Happy Customers

Wonderful Years in Business